Hotline

13863256262preparation of membrane switch before printing

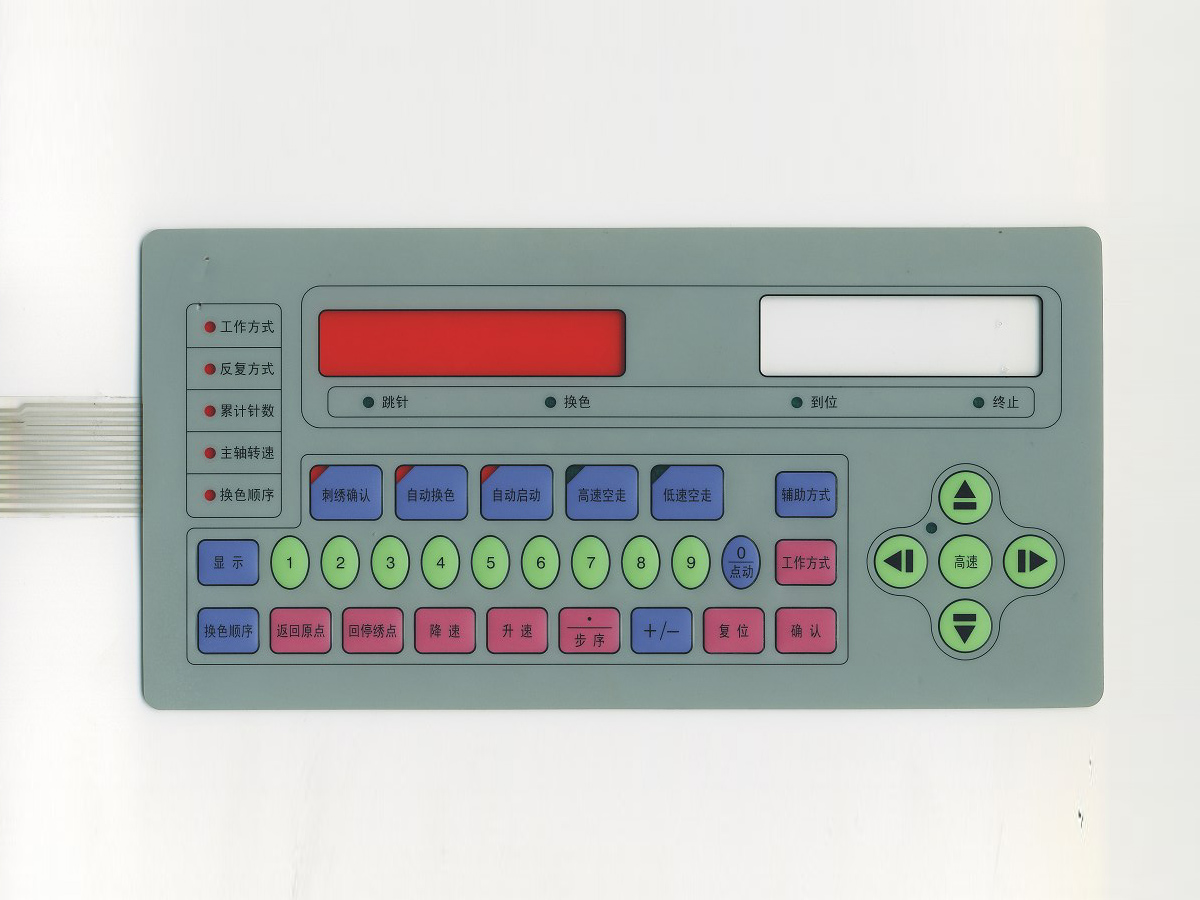

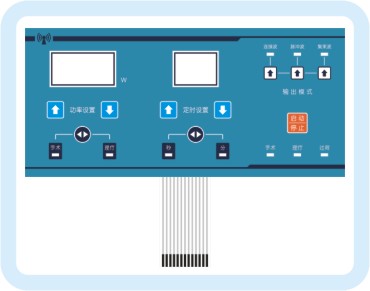

membrane switch is a widely used accessory in electronic products. membrane switch belongs to contact switch, which is generally made b…

1. the membrane switch products in the future will be more integrated, modular and intelligent, the detection standards will be more and more demanding, and the requirements for printing accuracy and material stability will be higher and higher;

2…

we compare the light touch switch from the following aspects: stamping - injection molding - cleaning - assembly - molding - inspection and other processes; the membrane switch process mainly includes: silk screen - die cutting - assembly - detection and other processe…

requirements for making membrane of membrane switch panel

as the panel of the membrane switch, it is mainly responsible for the decoration and protection of the product appearance, s…

1) planar contactless membrane switch

sense type: long service life, but no touch;

2) film convex tactile type: good tactility, but relatively short service life;

3) convex frame type …

the process flow of the membrane switch is pided into four parts: film design, screen making, screen printing and assembly. only by mastering the operation technology of each process can the printing quality be guaranteed.

i…

color matching and selection of membrane switch

the color of the membrane switch panel layer is printed on the reverse side of the membrane by screen printing with special ink.

in ter…

formulation of standards for membrane switches in the electrical industry:

the membrane switch is a multilayer structure (plane) (non lock making) key switch composed of a certain el…